Gardening Tips

5 Important Tips for Sawing Logs

Use the correct saw for the job

It is important to take into consideration the types of woods you are sawing and the type of saw you are using for the job. Here is a list of saws and what they are most appropriate for cutting:

- Hand saws: These are versatile saws that can be used for cutting a variety of woods. They are best for cutting small logs and for making precise cuts.

- Crosscut saws: Crosscut saws have a finer tooth pattern and are best at cutting hardwoods such as oak, maple, and hickory.

- Ripsaw: Designed with a coarser tooth pattern, Ripsaws are best used for cutting softwoods such as pine, spruce, and cedar.

- Bow saws: These saws are designed for cutting large logs and hardwoods.

- Chainsaws: Powerful saw that can cut through large logs quickly, good for cutting softwoods, such as pine and spruce.

- Reciprocating saws: These saws have a reciprocating blade which is best for cutting irregular-shaped logs, demolition work, and cutting metal.

- Jigsaw: Jigsaws are used for cutting curves, irregular shapes, and plywood.

- Band saws: Band saws are used for sawing curves into thick or thin lumber, they also can be used for resawing and making irregular and precise cuts.

It’s important to note that different saws may have different capabilities and are best suited for different types of wood cutting tasks. It’s always best to read the manufacturer’s instructions and recommendations for the saw you’re using.

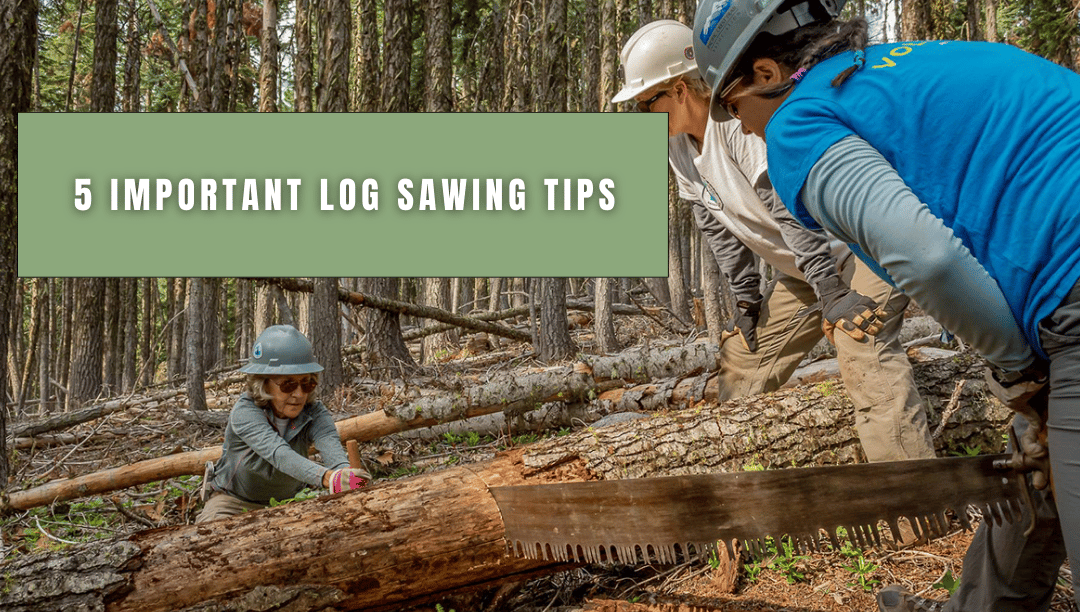

Wear appropriate workwear and safety protection

When working with potentially dangerous equipment it is always essential to wear protective clothing and gear to ensure that you don’t incur any injuries. Here is a list of things that you should be wearing when you are sawing logs:

- Eye protection: To protect your eyes from flying debris, sawdust, and other hazards, safety glasses or goggles always be worn.

- Ear protection: Earplugs or earmuffs should be worn to protect your ears from loud noises, especially when working with power saws.

- Gloves: To protect your hands from cuts, scrapes, and splinters, it is important that you you wear heavy duty gloves.

- Hard hat: A hard hat should be worn to protect your head from falling debris, branches, or other hazards. This is extremely important as hard hats can protect you from dangerous and potentially fatal injuries.

- Boots: Wearing steel-toed boots or other heavy-duty footwear can protect your feet from falling debris, sharp objects, and other potential hazards.

- Long-sleeved shirt and trousers: In order to protect your arms and legs from cuts, scrapes, and other hazards, long-sleeved shirts and pants should be worn.

- Reflective vest: If you are working in low-light or dark conditions, reflective vests are essential to improve visibility and reduce the risk of accidents. It is best practice to wear a reflective vest at all times, even during the day when working with dangerous equipment. This is in order to stand out so that other workers can see you at all times for further safety.

- Respiratory protection: If you’re working with sawdust or other particulate matter it is vital that either a dust mask or respirator is worn.

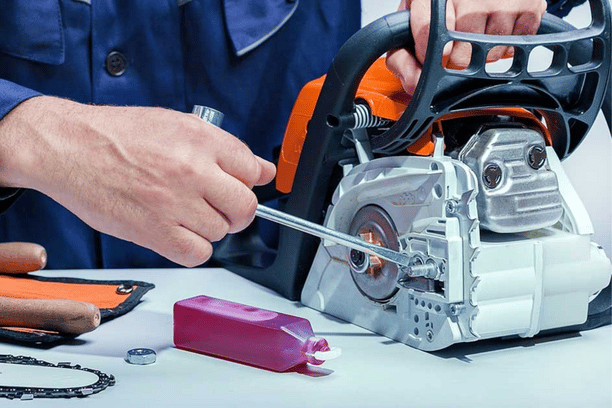

Make sure your sawing equipment is working correctly

Making sure your sawing equipment is functioning and maintained properly has multiple benefits and can prevent a lot of problems from occurring. Here are some reasons why:

- Safety: Equipment is less likely to malfunction or break down when maintained properly, greatly reducing the risk of accidents and injuries.

- Efficiency: Equipment in good working condition operates at peak performance, which can increase productivity and reduce downtime.

- Cost savings: Regularly maintaining and repairing equipment can help extend its life and reduce the need for expensive replacements.

- Compliance: Sawing equipment is required to comply with specific industry regulations and standards in some cases. It is a necessity that you are aware of whatever standards in place in your location/workplace and that your equipment conforms to these standards.

- Reputation: Using equipment that is in good working condition can help to maintain a professional image and can help to build trust with clients and customers. If you were to turn up to a job with poorly maintained equipment then it would look bad for your reputation. Especially if the equipment failed.

Clear the area and dispose of debris and sawdust

Clearing the area of debris and sawdust is a good way to ensure that you work is followed through properly and safely. Here are some reasons why:

- Safety: Removing rocks, branches, or other obstacles from the area can greatly reduce the risk of accidents and injuries. These obstacles can damage the saw or cause it to malfunction, which can lead to serious injuries for the operator or those nearby. Using a woodchipper or garden shredder is a convenient way to make room and to make waste easier to move and dispose of. It is also important to keep in mind that any sawdust produced could present a potential fire hazard, so be sure to clear it away and dispose of it safely.

- Damage Prevention: By removing debris that could get in the way you can help to prevent damage to the saw and other equipment, which can save money on repairs and replacements.

- Better Visibility: Cleaning up debris sawdust can make it a lot easier to see what you’re doing. This will improve accuracy and precision when sawing the logs.

- Compliance: Most Health and safety and Fire Safety standards require employers to keep walkways, passageways, storerooms, and service rooms in a clean and orderly condition.

Use a saw horse or workbench

Using a sawhorse or workbench are good for keeping logs stable and at a comfortable height for cutting. Here are several reasons why it’s recommended that you use one:

Safety: Sawhorses and workbenches provide a stable surface for logs to rest on while they are being sawn. This can help to prevent the logs from rolling or shifting during the sawing process, which can greatly reduce the risk of accidents and injuries.

Efficiency: A sawhorse or workbench can help to hold the logs at a comfortable height and angle for the operator, which can reduce the amount of time and effort required to saw the logs, and increase productivity and convenience.

Damage Prevention: They can also help to protect the logs from damage as they are being sawed, which can help to preserve the quality of the wood.

Better posture and movement: Saw operators can maintain a better posture and movement while sawing, which can help to reduce the risk of injuries and improve the overall work quality.

Vielen Dank für den Beitrag. Ich möchte mit einer Seilsäge ein Rohr durchschneiden. Die Checkliste auf was ich alles achten muss und welche Sicherheitsvorkehrungen ich treffen sollte, haben mir sehr geholfen.